On-line gas-liquid mixer

|

On-line gas-liquid mixer |

|

■

A revolutionary on-line, high efficiency gas-liquid mixer that does not

need a reacting tank/pool.

■ Co-Mixer turns in-taken air into bubbles of diameter less than 0.2 mm. |

|

|

|

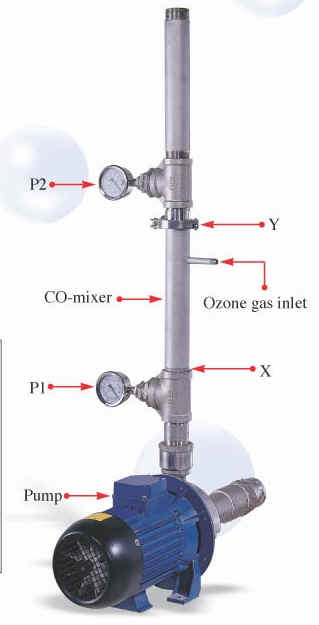

What are Co-Mixer and COLP? There are two available configurations of the AirTree on-line gas injector, which are coaxial mixer (Co-Mixer) and coaxial liquid pressurized mixer (COLP).

The Co-Mixer is an on-line vacuum suction injector. It can be simply and directly adapted to customer’s pump system. The gas is injected at the outlet of pump that prevents the pump from chemical damage and gas choking. Co-Mixer has low lose in both water flow rate and pump head pressure. For ozone application the dissolving tare is greater than 95%.

In order to homogenously mix the gas into the water, Co-Mixer is utilized to create a low-pressure in the suction process, so that the gas at the point of liquid-gas mixture is at lower than atmospheric pressure. This in turn results in the volume of gas being shrunken by the water pressure. When tested with air, more than 90% of the un-dissolved air forms into hyperfine bubbles of diameter less than 0.2 mm, which as suspended in the water instead of bubbling up. The volume shrunken of the bubble increases the total contacting surface resulting in highly homogenous mix, efficiency dissolution. This unique feature can be applied, for example, to replace H2O2 with ozone for disinfecting water pipe line.

|

|

Co-Mixer @ 5 HP pump 86.6% on-line dissolving rate water flow rate 486 l/min, ozone 67.3 g/h |

||

|

Results compared with a conventional Venturi tube

|

|

|

What is coaxial liquid pressurized mixer, COLP?

COLP is an integrated design that includes CO-mixer and liquid pressurized separator. The gas is on-line injected into CO-mixer to mix with liquid. The liquid then is confined by a structured pipe inside the separator to flow to near the top, separating the un-dissolved gas and also building up a positive pressure at the top region of the separator. When the system is at balance, the total pressure is higher than atmospheric pressure by an amount of liquid pressure that is generated by the pump system. The positive pressure helps to increase the dissolving rate, and push the liquid to continuously flow out of the separator. Alternatively, the positive pressure can be released through a de-gas outlet to remove the un-dissolved oxygen when used in dissolving ozone, and to remove ozone or oxygen when used in de-gas application.

|

|

|

Oxygen off-gas by intaken Nitrogen in one ton of water

Ozone off-gas by intaken Nitrogen in one ton of water

|

| Benefit for using Co-Mixer and COLP |

|

The AirTree coaxial on-line mixer, Co-Mixer/COLP, is ideal for ozone-water mixing because it optimizes ozone-water mixing while eliminating the leakage of un-dissolved ozone gas. It creates a highly homogenous gas-water mixture, which conventional Venturi type mixing tubes cannot compete with. Due to the extremely high efficiency and large gas/water intake rate, the AirTree coaxial on-line mixer also eliminates the need for reacting tank/pools, required of most conventional designs. |

|

|

|