Q5:

Our water flow is 6 gallons per minute. We are filling tanks at this rate.

A5:

According to your 6 gallons per minute's water flow rate, we would suggest to you to employ Model: Bob-7, it is capable of producing 0.9 g ozone dissolved in water per hour, and it is sufficient to meet your requirement of 0.1 mg/l of ozone in water. Please visit our website for more information regard to the Bob-7 ozone generator. Please feel free to contact us if you require further information.

Q6:

We would like some information on an ozone machine for recycling and reusing waste water. (Water we use for washing trucks to take out Bacteria and smell)

A6:

Ozone not only is used to treat waste water for reusing, the ozonated water can do the truck wash to effectively take out bacteria and smell. That is, washing truck with ozonated water. Please see the scheme of ozonated water setup in the attachment. In order to work out a proposal, please inform us what is your water output flow rate (gallon/min or tons per hour) used in truck washing? What is the total amount of water per day? What is the HP of the water pump? What is the diameter of pipe of the water pump? E-mailing a digital photo of the site to us, if it is possible, could help lot.

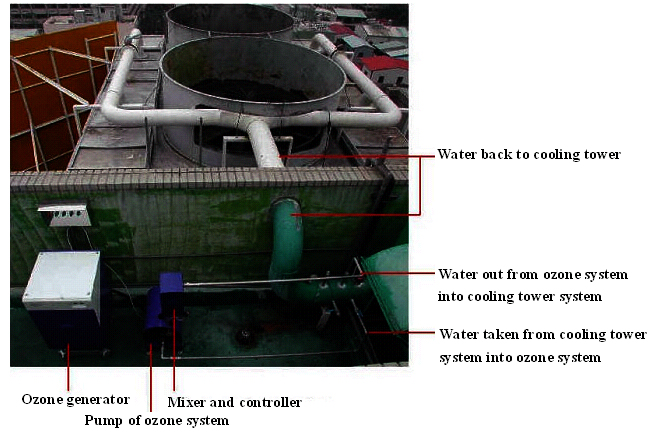

Cooling tower ozonator

Operating cost analysis of chemical treatment system for cooling tower:

1. The water circulation rate (Q): 13 l/min/RT x 2,500 RT = 32,500 l/min

1 RT = 13 l/min = 0.78 m3/h

2.

Evaporation loss (Q1): ![]() T

/ 5.8 x

1% x Q = 279.5

l/min

T

/ 5.8 x

1% x Q = 279.5

l/min

(![]() T

=

change in temperature,

T

=

change in temperature, ![]() T

=

5℃)

T

=

5℃)

3. Drift loss (Q2) = 0.001 x 1% x Q = 0.325 l/min

4. Cycles of concentration (COC) = 5

If COC is unknown, default is 5.

5. Blowdown rate (Q3) = 0.9 / (COC - 1) = 0.9 / (5 - 1) = 0.225

6. Blowndown load = 1

7. Blowndown (Q4) = Q3 x Q / 100 = 73.125 l/min

8. Make-up water (Q5) = (Q1 + Q2 + Q4) x (365 x 24 x 60 x 1) = 185,510 CDM/yr

9. Annual cost of make up water (Q6) = water cost in $/CDM x Q5

10. Chemicals cost (Q7): $/month x 12 = $/yr

Total annual operating cost = Q6 + Q7 = $/yr

Note: Repair and maintenance cost is not included.

II. How to calculate the operating cost of chemical treatment system for cooling tower?

Operating cost analysis of ozone treatment system for cooling tower:

1. The water circulation rate (Q): 13 l/min/RT x 2,500 RT = 32,500 l/min

1 RT = 13 l/min = 0.78 m3/h

2.

Evaporation loss (Q1): ![]() T

/ 5.8 x 1% x Q = 279.5

l/min

T

/ 5.8 x 1% x Q = 279.5

l/min

(![]() T

=

change in temperature,

T

=

change in temperature, ![]() T

=

5℃)

T

=

5℃)

3. Drift loss (Q2) = 0.001 x 1% x Q = 0.325 l/min

4. Cycles of concentration (COC) = 10

5. Blowdown rate (Q3) = 0.9 / (COC - 1) = 0.9 / (10 - 1) = 0.1

6. Blowndown load = 0.9

7. Blowndown (Q4) = Q3 x Q / 100 = 0.1 x 32,500 / 100 = 32.5 l/min

8. Make-up water (Q5) = (Q1 + Q2 + Q4) x (365 x 24 x 60 x 0.9) = 147,742 CDM/yr

9. Annual cost of make up water (Q6) = water cost in $/CDM x Q5

10. Electricity consumption:

Power consumption of cooling tower ozone equipment kW/h + Pump power consumption kW/h

11. Electricity cost (Q7):

Electricity consumption kW/hr x daily operating hours x 365 x unit price of electricity = $/yr

Total annual operating cost = Q6 + Q7 = $/yr

C-Lasky C-L010 mode applied to air treatment

Because

C-Lasky supplies high concentrated ozone it is suitable for

instantaneous air cleanness or setting the timer for large space air

disinfecting and dispelling insects at night. It has been widely applied

to air clearness, goods reservation and disinfectant bacteria in places

such as, office, library, hospital, hotel room, warehouse, supermarket,

restaurant, and food industry.

When used for air treatment the C-L010 is capable of producing 150 cubic

meters per minutes of ozonated air at 0.05 ppm air concentration. The

concentration maybe increased up to 0.25 ppm if an external oxygen gas

supply is used. When applied to large area, it is recommend that ozone

is dispersed via 15 holes (one mm in diameter) along the length of a

1/4" O.D. Teflon tube. All of them can easily add in to various

systems depending on the request of ozone concentration and ozone

production.

G-Sapphire P-20 applied to water disinfection

P-20 can be coupled to water storage tank to provide disinfected water for the need of drinking water, pharmaceutical grade water, water for food processing etc. One of typical application was presented in "Proceeding of the International Ozone Association Pan American Group 2001 Annual Conference," titled "Case Study of Sterile Purified Water Disinfection with Ozone in Pharmaceutical Applications" by Chiou-Hwa Su.